Standard T Slot Dimensions Metric

Standard Metric Keys & Keyways for Metric Bores with One Key. Couplings (Page 2 of 2) All Types 427-140 Reo a 21 (P eso) oola e el 11 pesees 2 Telepoe 22 a 22 eoo Key & Keyway Dimensions – Millimeters Coupling Hub Keyway Dimensions – Inches Shaft Diameter “D” Key Size Nominal Keyway Width Hub “W” Keyway Depth Hub “T2”.

- See Page 2 for Optional P9 & D10 Keyway Dimensions H W R T2 T =D+ T2 T D. Standard Metric Keys & Keyways for Metric Bores with One Key. Couplings (Page 2 of 2) All Types 427-140 Reo a 21 (P eso) oola e el 11 pesees 2 Telepoe 22 a 22 eoo.

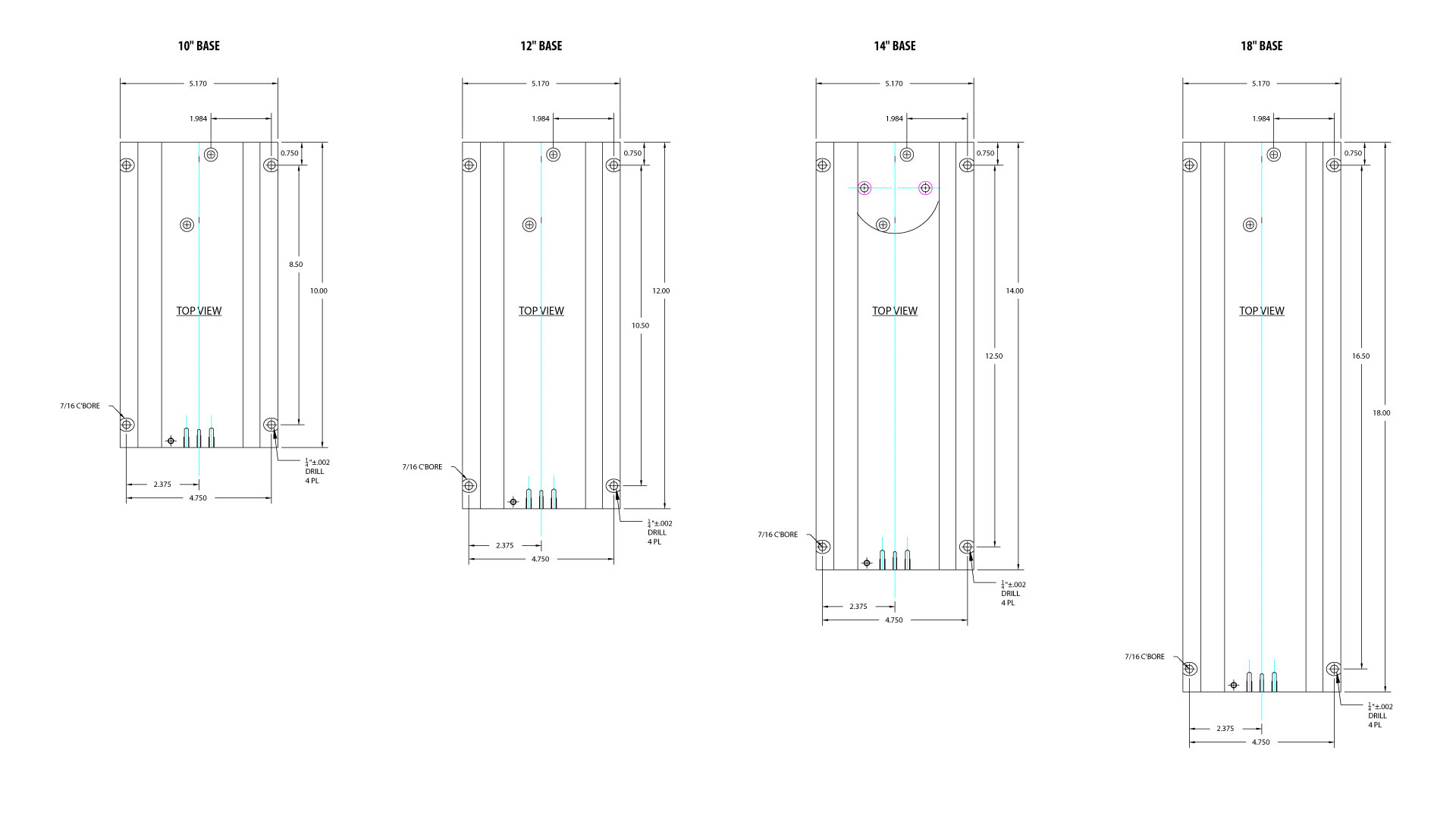

- Table T-slot centerline distance (lathe and mill) 1.5″ T-slot nominal dimensions.Note: The T-slots are extruded into the material. Table surfaces are machined for flatness, but the slots themselves require no additional finishing processes. Slot width, top:.25″ T width, bottom:.40″ Upper slot depth:.10″ T Slot.

- Metric T Slot Aluminum Profiles

- Connectors

T Slot Dimensions Standard

- Fasteners

- Accessories

- Frame to Floor

- Panel Accessories

- CarboSix Carbon Fiber

A major advantage of using modular aluminum framing over welded steel is that the t-slot that allows infinite mounting locations for accessories. Common examples of these are in-fill panels, interlock switches, pneumatic or electronic components, mechanical components, etc. Depending on the profile series chosen you can select a wide variety of thread sizes to best fit the component you are trying to mount. The hardware is typically categorized by a t-slot width designator within the product ID that will allow a fast understanding of commonality with a particular profile size.

Ex: TN10M6 - a t-nut for the 10mm wide t-slot that is found on 40mm profiles and up and will show a symbol. Also, this t-nut has an M6 thread and will work on any profile showing the corresponding t-slot symbol allowing fast reference.

Once the t-slot width is identified it’s a simple choice for thread size based on the component being mounted & the style of fastener desired. The most common fastener type is the t-nut. This is a post-assembly or drop-in style that can be inserted anywhere the t-slot is available. This series nut has an elliptical shoulder which, with a 90° turn, aligns within the upper portion of the t-slot & locks into the t-slot with a strong, vibration proof & electrically conductive connection.

Roll-in or Drop-in t-slot nuts function in a similar fashion with the additional benefit of having either a leaf-spring, ball-spring or set-screw for retaining their position in the t-slot. This is very beneficial when used for mounting table-tops or surface mounted plates as you don’t want these fasteners to move when the top is un-bolted. These also hold their position when used in a vertical t-slot & won’t slide down or fall out.

T-Bolts are commonly used & function just as the t-nuts do in that they have a similar shaped head with the locking feature & a male thread available in various lengths. Use the –“W” suffix & a flange nut will be included to assist in the mounting of your clad-on panel or other equipment. As you can see below, here are all the aluminum fastener types we carry.

Fastener Types We Carry

• Roll-In Nuts

• Drop-In T-Nuts

• T-Bolts

• T-Slot Nuts

T-Nuts: -Different components can be fastened to the t-slot. This could be removable panels, switches, etc. |

Roll-in T-nuts (Ball-Spring): -Made for metric profiles. Roll-in T-nuts (Leaf-Spring): - Made for metric and inch profiles. |

Square T-nuts: -Made for metric profiles. |

Drop-in T-nuts (Leaf-spring): -Made for inch profiles Drop-in T-nuts (Ball-Spring): -Made for inch profiles. Drop-in T-nuts (Set Screw): -Made for inch profiles. |

T-slot Nuts (Slide-in): -Made for metric profiles. |

Standard T-nuts: -Made for inch profiles. |

Economy T-nuts: -Made for inch profiles. |

Double Economy T-nuts: -Made for inch profiles. |

T-bolts: -Made for both metric and inch profiles. |

| M-LOK | |

|---|---|

| Type | Attachment System |

| Place of origin | United States |

| Production history | |

| Designer | Magpul Industries |

| Designed | 2007–2014 |

| Produced | 2014–present |

M-LOK, standing for Modular Lock, is a free licensed[1]firearmrail interface system developed and patented by Magpul Industries.

M-LOK allows for direct accessory attachment onto the 'negative space' (hollow slot) mounting points, and is a competing standard to VLTOR's open sourcedKeyMod system for replacing the ubiquitous Picatinny rail in some applications.[2] Compared to the Picatinny rail system, both M-LOK and KeyMod enable the user to have a slimmer, lighter, smoother and more fenestratedhandguard/fore-end with accessories mounted only where needed, whereas a Picatinny handguards typically will have rail slots for its whole length resulting in a heavier and bulkier handguard with sharp edges and poorer barrel ventilation.

The M-LOK system can be seen as an evolution of the Magpul Original Equipment (MOE) system, but the two are not fully compatible. Though newer M-LOK accessories can be used on older MOE slot handguards if an adaptor plate is used, there is no adaptor available for using older MOE accessories on the newer M-LOK handguards.

History[edit]

A prototype of the MOE slot was revealed by Magpul in late 2007 together with their Masada Concept Rifle (which would later be known as the Adaptive Combat Rifle). The MOE slot system was released by Magpul in 2009 as a feature on their MOE handguards, and at the same time compatible accessories such as Picatinny rail sections, direct MOE mounted light mounts, grips, bipod studs, etc. were released.

The MOE slot standard was never officially released, and a drawback to the system was that the rear side of the panel had to be accessed in order to mount accessories, limiting its application. The MOE slot system uses a weld nut which has to be placed manually on the inside of the handguard before mounting, making the slot system unsuited for applications such as free-floating handguards. Also, depending on the accessory item, the spacing increments between the MOE slots were not small or uniform enough to adjust the desired placement of accessories.

Acknowledging shortcomings of the MOE systems, Magpul drafted M-LOK as a new and improved mounting standard which was released in 2014 replacing the existing MOE slot. The M-LOK rail specification included metric dimensions instead of imperial, and utilizes a T-slot nut capable of only 90-degree rotation, reinforced by thread-locking fluid, making it suited for applications on free-floating handguards. It was designed to work with both metal and polymer parts.

In 2016, Colt Canada developed and released the Modular Rail Rifle (MRR) that uses a monolithic upper receiver with the M-LOK attachment system.[3] In 2017, several companies produce M-LOK handguards as well as accessories like Picatinny rail strips, vertical foregrips, bipods, sling adaptors, and flashlight mounts.[4]

In 2017, a summary report of testing conducted by NSWC-Crane for USSOCOM indicated that, while comparable in endurance and rough handling testing, M-Lok greatly outperformed Keymod in repeatability, drop testing and failure load testing.[5]

Licensing[edit]

While M-LOK is free licensed, it is not open source, and thus manufacturers must acquire a license from Magpul before making products using the M-LOK standard. Magpul claims this gives them more control in assuring that all M-LOK products are made to specifications ensuring compatibility. Program participation is open to any interested manufacturer.

Technical specifications[edit]

Rail specifications[edit]

The slot dimensions (used on handguards, etc.) are available on the web.[6] The slots provide metric 20 mm (0.79 in) length intervals, and accessories can be mounted either within a slot or bridging between slots, making it possible to adjust the position of accessories in smaller intervals than the length of the slot. The slots on an M-Lok handguard are approximately 32 mm (1.260 in) long and 7 mm (0.276 in) wide and space 8 mm (0.315 in) from each other. The radius of the corners is approximately 2.38 mm (0.094 in).[7][8][9]

Attachment specifications[edit]

The quarter-turn T-slot nuts have different torque specifications depending on the handguard material:

- 4.0 N⋅m (35 lb⋅in) for attaching metal accessories to metal handguards.

- 1.7 N⋅m (15 lb⋅in) for attaching polymer or metal accessories to polymer handguards.

- 1.7 N⋅m (15 lb⋅in) for attaching polymer accessories to metal handguards.

Attachment screws made by many U.S. manufacturers are often either #8-32 TPI or 10-24 TPI UNC threads, which respectively have major thread diameters of 0.1640 inches and 0.1900 inches (4.166-0.794 mm and 4.826-1.058 mm expressed in metric designation). Many M-LOK screws on the international market instead use either M4 or M5 metric threads to reduce cost.

The tool required for mounting, in addition to the thread size, also depends the screw head type. Hex keys are used extensively in the firearms industry, but metric and imperial hex keys as a general rule are not compatible. It is possible damage the tool and screw by selecting a tool that is too small for the fastener, which can be done by using an Imperial/customary tool on a metric fastener, or the converse. An exception to this is 4 mm hex keys, which are almost the exact same size as 5⁄32 in (3.97 mm). In many industries, this makes 4.0 mm (5⁄32 in) hex keys preferred for consumer products because end users can successfully use an imperial key on a metric fastener, and vice versa.

| Hex key spanner (wrench) size | ||||

|---|---|---|---|---|

Thread type | Socket head cap screw | • Button head cap screw • Flat head counter- sunk cap screw | ||

| M4 | 3 mm | 2.5 mm | ||

| M5 | 4 mm | 3 mm | ||

| #8-32 TPI | 9/64' (3.57 mm) | 3/32' (2.38 mm) | ||

| #10-24 TPI | 5/32' (3.97 mm) | 1/8' (3.18 mm) | ||

While screw and slot dimensions are available on the web, the T-slot nut dimensions are currently under review by the US State Department to determine whether it should be regulated by ITAR, and until it is clarified drawings are only available to US citizens.

M-LOK handguard and attachment parts

M-LOK approximate slot dimensions. (Primary measurements in millimeters, inches in parenthesis).

Standard Key Slot Dimensions

See also[edit]

- Rail Integration System, generic term for a system for attaching accessories to small firearms

- Weaver rail mount, early system used for scope mounts, still has some popularity in the civilian market

- Picatinny rail (MIL-STD-1913), improved and standardized version of the Weaver mount. Used for both for scope mounts, and for accessories (such as extra sling mounts, vertical grips, bipods etc.) Major popularity in the civilian market.

- NATO Accessory Rail- further development from the MIL-STD-1913

- UIT rail, an older standard used for mounting slings particularly on competition firearms

- KeyMod - competing standard open standard design to M-LOK for mounting accessories

- Zeiss rail, a ringless scope mounting standard

References[edit]

| Wikimedia Commons has media related to M-LOK. |

Standard T Slot Dimensions Metric Wrench

- ^'Magpul Industries - M-LOK'. Archived from the original on 4 December 2017. Retrieved 6 June 2016.

- ^KeyMod vs. M-Lok: The Next AR Rail Standard by Chris Baker, November, 19, 2014

- ^Colt Canada Modular Rail Rifle (MRR)

- ^M-LOK Outselling KeyMod about 3 to 1, 28 January 2016

- ^Details On The USSOCOM Sponsored KeyMod vs M-LOK Test Conducted at NSWC-Crane, 5 May 2017

- ^Magpul Industries - M-LOK DESCRIPTION AND FAQ DOCUMENT[permanent dead link]

- ^'magpul.com - M-LOK 2015 FAQs'(PDF). Archived from the original(PDF) on 7 April 2019. Retrieved 7 April 2019.

- ^M-Lok dimensions

- ^Magpul M-LOK estimated dimensions